Unlocking the Potential of Membrane Rubber in Modern Industries

Membrane rubber has emerged as a critical material in various sectors, thanks to its unique properties and versatility. From manufacturing to biotechnology, the applications of membrane rubber are extensive, and its importance cannot be overstated. In this article, we will delve into the nature of membrane rubber, its various forms, its benefits, and its applications across different industries.

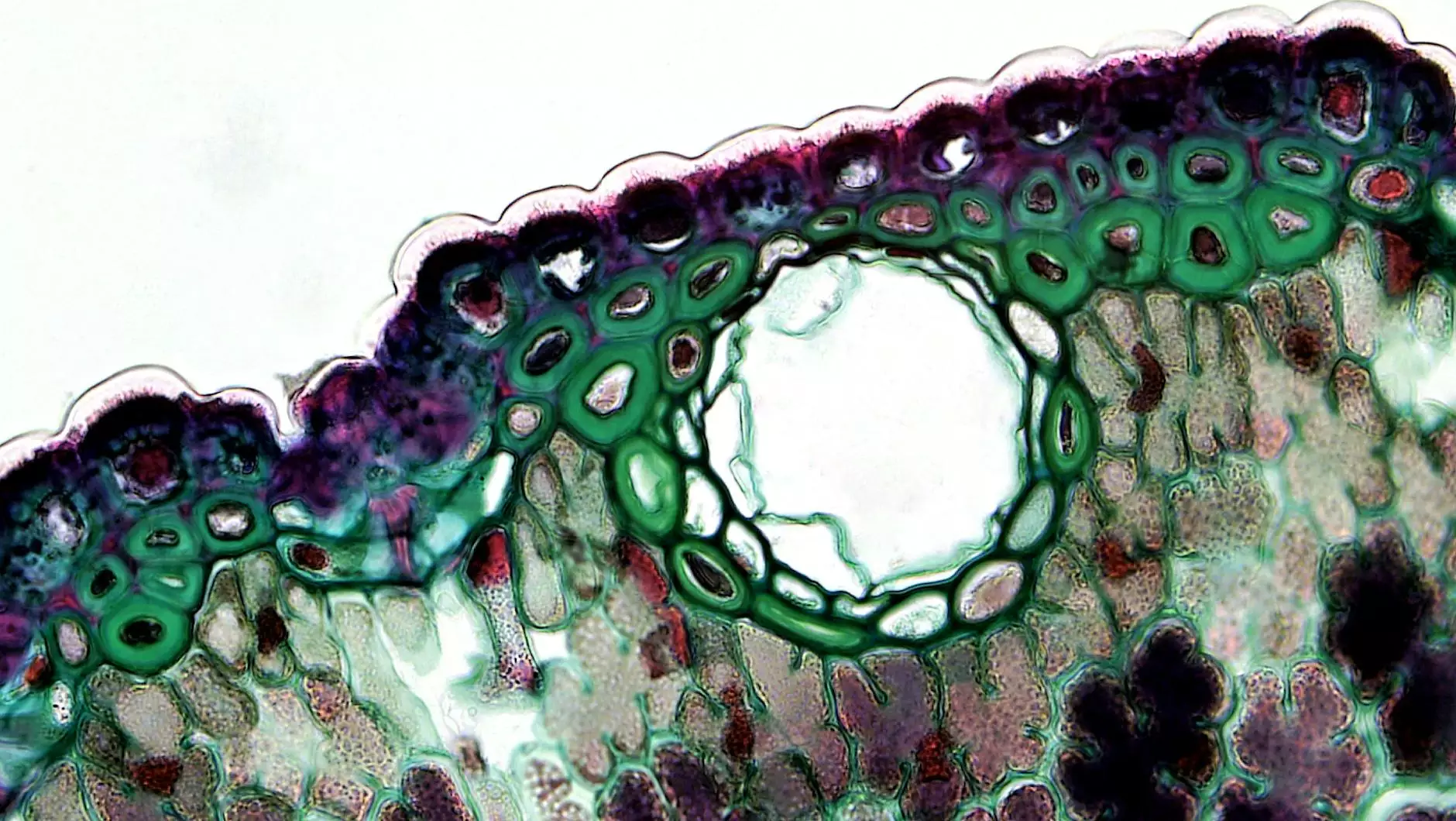

What is Membrane Rubber?

Membrane rubber refers to specialized rubber materials used primarily in creating membranes that serve functional roles in various applications. These membranes can be manufactured from different types of rubber, including silicone and natural rubber, each offering distinct advantages and properties suited to specific tasks.

Types of Membrane Rubber

Understanding the different types of membrane rubber is essential for selecting the right material for your specific needs. Below are the most prevalent types:

- Silicone Membrane: Known for its high-temperature resistance and flexibility, silicone membranes are ideal for applications involving heat and pressure.

- Natural Rubber Membranes: These membranes are praised for their durability and excellent elasticity, making them suitable for various industrial applications.

- Rubber Membranes: General rubber membranes provide a balance of strength and flexibility, being adaptable across multiple sectors.

- Specialty Membranes: Customized rubber membranes designed for specific applications, such as medical devices or food processing.

The Benefits of Membrane Rubber

Membrane rubber offers a multitude of benefits, making it a preferred choice in various industries. Here are some key advantages:

1. Versatility

The versatility of membrane rubber allows it to be used in numerous applications, from automotive to aerospace. Its ability to adapt to different environments is unmatched.

2. Chemical Resistance

Many types of membrane rubber exhibit exceptional resistance to chemicals, oils, and solvents, which is crucial for industries like pharmaceuticals and chemicals where material degradation can lead to substantial losses.

3. Temperature Tolerance

Particularly silicone membranes, provide excellent performance under extreme temperatures, making them suitable for high-heat applications.

4. Flexibility and Durability

Rubber membranes are known for their elastic properties and ability to withstand significant stress without deformation, resulting in longer-lasting products and lower replacement costs.

5. Cost-Effectiveness

Due to its durability and performance, using membrane rubber can be a cost-effective solution, reducing maintenance and replacement needs over time.

Applications of Membrane Rubber Across Industries

Membrane rubber plays a pivotal role in various sectors. Below are some notable applications:

1. Biomedical Applications

In the biomedical sector, membrane rubber is utilized in devices such as valves, seals, and specialized diagnostic equipment. Its biocompatibility ensures that it can be safely used without causing adverse effects on the body.

2. Food and Beverage Industry

Membrane rubber is crucial in the food industry, where it is used to create hygienic seals and membranes that prevent contamination while allowing for necessary gas exchange in packaging. Natural rubber membranes are particularly popular in this sector due to their non-toxic qualities.

3. Automotive Sector

In the automotive world, membrane rubber is used in various applications such as gaskets, seals, and weatherstripping. The flexibility and durability of these materials help maintain vehicle integrity against adverse environmental conditions.

4. Electronics Manufacturing

The electronics industry benefits from membrane rubber through its use in keypads, gaskets, and other components that require precise control over environmental factors like dust and moisture ingress.

5. Industrial Applications

Many industrial processes require reliable seals and membranes to operate efficiently. Membrane rubber is extensively used in valves, pumps, and other machinery where robust, flexible materials are essential for performance.

Choosing the Right Membrane Rubber for Your Needs

When selecting the appropriate type of membrane rubber for your application, several factors should be considered:

- Temperature Requirements: Understand the operating temperature range your application will encounter.

- Chemical Exposure: Evaluate the types of chemicals the membrane will be exposed to and select materials accordingly.

- Mechanical Properties: Determine the tensile strength, elasticity, and durability required for your application.

- Regulatory Standards: Ensure the selected membrane rubber complies with any necessary industry standards or regulations.

Conclusion: The Future of Membrane Rubber

As industries continue to evolve, the demand for high-performance materials like membrane rubber will undoubtedly grow. Innovations in material science are leading to the development of even more advanced rubber formulations that can withstand harsher conditions and meet the needs of specific industries. From the automotive sector to healthcare and electronics, the applications of membrane rubber are vast and varied.

For businesses looking to invest in products made from membrane rubber, it is vital to partner with reliable suppliers who understand the intricacies of membrane technology. At vacuum-presses.com, we specialize in providing high-quality membranes, including silicone and natural rubber options, tailored to meet your specific needs. Explore our extensive range, and let us help you harness the benefits of membrane rubber in your operations.

Contact Us

For more information on our products and how they can benefit your business, please feel free to reach out to us via our website or contact us directly. We look forward to helping you find the perfect membrane rubber solution for your needs.